Third Project Interview

Capacity planning is an essential process of operations management. Through this process, a company determines its output level given the resources it can access at a given moment (Reid & Sanders, 2016). This helps a business to determine how effectively it can meet the customers’ demand and develop strategies to cover the potential capacity deficits that may affect production (Slack et al., 2010). The third and final project interview focuses on the Zara facilities and the company’s alignment strategies. This essay evaluates the results of this interview focusing on three key areas; stakeholders associated with the operations management in these areas, the company’s operational tactics, and the company’s operational processes and practices.

Do you need help with your “Third Project Interview capstone project”? Connect with us.

Describe stakeholders associated with assessing operations management.

There are several stakeholders whose role is essential in the Zara facilities management process. First, the company plans its production capacity based on market demand. Zara has market analysts evaluate potential requests based on upcoming fashion trends. Capacity planning begins with the identification of capacity requirements. A business must understand the order in the market to avoid manufacturing in surplus or deficit (Reid & Sanders, 2016). According to the interviewed manager, Zara uses quantitative tools to evaluate the expected market demand. They use data from the previous sales made from new releases to forecast the expected demand for their new products.

The company’s designers also play an essential role in facilities management. Once the demand forecasts have been made, the designers ensure the company has good designs in time for production. Regardless of how excellent the facilities of Zara are, the company cannot meet demand if the new plans are not developed in time. Therefore, the role of the designers is vital in this part of the production process.

The operations management at Zara plays a role in the facilities management by ensuring adequate resources are available for every production season. The company has thousands of production plants, which usually have all the amenities for production to be done on time.

Summarize operational tactics and strategies from an interview.

Zara uses various tactics and strategies to ensure that its facilities are adequate and can meet the demanded capacity of products every season. First, the interviewed manager stated that Zara has its production plants. The company does not lease or outsource this responsibility; instead, they have developed thousands of production plants in various parts of Europe and Asia. This strategy is effective for the company because its production occurs very frequently. Therefore, it is more effective if the company has reliable production capacity instead of transferring this responsibility to strategic partners.

Another strategy used by the company is having numerous production facilities. The capacity demand for Zara is very high. With over 10,000 retail stores and online sales, the company has a very high demand for production. According to the manager, most of the stock is apparent within just two weeks, at least in the store he manages. With many production plants, the company can quickly produce a large amount of stock.

The locations of the production facilities are also strategically selected. The manager stated that Zara goes for cost-effective production locations, allowing them to maintain competitive product prices. Their central location strategy is to choose places where labor is cheap. Cheap labor is one of the main factors that motivate manufacturing businesses to choose specific locations. With cheap labor, they can maintain a low production cost. Zara is one of the businesses that use this strategy. The interview uncovered that Asian countries are Zara’s central target production locations because of the low production costs in these locations.

Zara also ensures that it meets its production demands through adequate staffing. Zara is an employer of tens of thousands of employees. The design process only involves over 300 designers who develop the prototypes to be produced for the market. The company is also adequately staffed at its production plants to ensure they can meet demand in time.

Summarize operational processes and practices from an interview.

Zara uses several tactics and processes to ensure successful facilities management and to align the operations process to the company’s mission. The company’s mission is to provide various fashion options so they can have exclusivity of choice. Therefore, the facilities planning for this company is done based on market needs. The company makes its decisions based on what customers want.

Zara’s processes and tactics also involve freeing up to 80% of the production plant capacity to meet the new demand. The company ensures that the facilities are available when there is an increased need to complete a new order. Zara’s tactics also involve taking advantage of globalization. Globalization is the process of integrating operations worldwide (Eriksen, 2018). Zara has production plants located in several countries, thus, taking advantage of the environmental benefits of each of its production locations.

Other Related Post: MBA Reflection

References

Eriksen, T. H. (2018). Globalization. In Handbook of Political Anthropology. Edward Elgar Publishing.

Reid, R. D., & Sanders, N. R. (2016). Operations Management, Binder Ready Version: An Integrated Approach. John Wiley & Sons.

Slack, N., Chambers, S., & Johnston, R. (2010). Operations management. Pearson education.

ORDER A PLAGIARISM-FREE PAPER HERE

We’ll write everything from scratch

Question

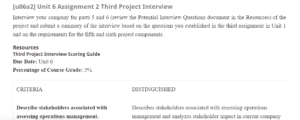

[u06a2] Unit 6 Assignment 2 Third Project Interview

Interview your company for parts 5 and 6 (review the Potential Interview Questions document in the Resources) of the project and submit a summary of the interview based on the questions you established in the third assignment in Unit 1 and the requirements for the fifth and sixth project components.

Third Project Interview

Resources

Third Project Interview Scoring Guide

Due Date: Unit 6

Percentage of Course Grade: 3%.

| CRITERIA | DISTINGUISHED |

| Describe stakeholders associated with assessing operations management. 33% |

Describes stakeholders associated with assessing operations management and analyzes stakeholder impact in current company practices. |

| Summarize operational tactics and strategies from an interview. 33% |

Summarizes operational tactics and strategies from an interview and describe how those support the company’s vision, mission, and strategic goals. |

| Summarize operational processes and practices from an interview. 34% |

Summarizes operational processes and practices from an interview and describe how those support a company’s mission and goals. |

POTENTIAL INTERVIEW QUESTIONS

Part One: Naming Your Company

(No Interview associated with this part.)

Part Two: Project Description

Some questions to consider for completing this assignment include:

- What is the company’s history and culture?

- Does it have a mission statement, and what is it?

- Who do they sell to, and what is the general profile?

- Who are their biggest competitors, and what is their profile?

- What is their market share for their immediate area and the industry?

- Others?

Part Three: Product Design

Some questions to consider for completing this assignment include:

- What is the product or service?

- How do they complete their product or service?

- How do they design their product or service?

- Make a flow chart.

- Others?

Part Four: Quality Control

Some questions to consider for completing this assignment include:

- How do they control the quality of the product or service?

- Do they use programs such as TQM, Six Sigma, or others?

- How do they train their employees to ensure product quality?

- Others?

Part Five: JIT Analysis

Some questions to consider for completing this assignment include:

- How do they receive their components or materials for their product or service?

- Do they have alliances or partnerships with other companies?

- Do they have JIT, and how do they use it?

- How are the parts integrated into the business process?

- Others?

Part Six: Facilities Analysis

Some questions to consider for completing this assignment include:

- Where are their plants located? Are they close to customers and materials? Transportation? Other essentials?

- What type of technology do they use throughout their company? Is there MRP, CADCAM, SAP, or other technology?

- Do they have any controls or systems to control their inventory?

- Others?

Part Seven: Company Alignment

Some questions to consider for completing this assignment include:

- What are the company’s core competencies?

- How well are the core competencies in alignment with the mission statement?

- Others?

Part Eight: Final Presentation

(No Interview associated with this part.)