Statistical Process Control Methods-Apple

Part 1: Process Evaluation

The Six Sigma methodology is applied in organizations to eliminate or minimize defects in various processes. Six Sigma utilizes two primary methods: DMAIC (define, measure, analyze, improve, and control) and DMADV (define, measure, analyze, design, and verify). New processes in an entity rely on the DMADV method. A company reaps numerous benefits by implementing Six Sigma in its operations. These include client loyalty, better management of time, less cycle time, motivation of employees, supply chain management, and strategic planning. The methodology is intended to lead to better quality, speed, cost efficiency, and client satisfaction. During New Product Development (NPD), Six Sigma prioritizes the customers’ needs through quality improvement and optimization of the company’s financial performance (Sabri, Mahmood, & Hasrulnizzam, 2018).

Apple’s manufacturing process is critical to its attainment of a competitive advantage. The method of developing new products at the company responds to the dynamic needs of clients, a constant need for innovation, improved technology, better functioning, and superior performance of products. NPD is a process that should be guided by information obtained from the market through the involvement of clients. In addition, the speed of developing products is critical due to the shrinking life cycle of products today.

Apple’s defects in the development of new products are primarily observed in the process. First, the process does not involve clients from the beginning. The highly secretive process of product development at Apple eliminates parties who are not critical to the process within the organization. However, clients are essential because the product is created for them. Secondly, the reduction of time that is taken during the process of development is vital to retaining a formidable competitive advantage and ensuring that the new products consume reasonable financial resources. Currently, Apple’s product development can be termed as extravagant because the designers are not limited to a budget (Panzarino, 2012). At the same time, there is constant redesigning, rebuilding, and retesting if there is a leakage of the prototype. This lengthens the time that a new product takes before it is introduced into the market and the resources that are committed to the process. In addition, some products are defective because they fail to serve the clients’ needs as expected, which reduces their acceptance in the market.

To improve this process, Apple needs to start the development of new products under the guidance of market information, which is obtained from research and development. While most of Apple’s product launches have received a warm welcome among its loyal clients., a few have disappointed the same clients. For instance, NeXT, the desktop computer that the late Steve Jobs developed, was perceived as too expensive and failed to fulfill all the client’s needs. The laptop had an optical drive instead of a floppy drive. This made it challenging to transfer work from another computer to the NeXT (Yousafzai, Ishrat, & Khan, 2011). This highlights a lack of commitment to offering clients precisely what they need, which leads to defects that make the new product undesirable.

Part 2: Evaluation of Control Chart and Process Metrics

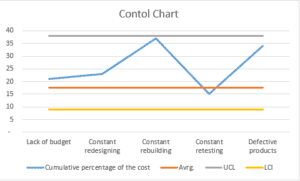

As can be seen from the charts, Apple Inc.’s production process is replete with several wastages that erode its competitive advantage. The presence of a point outside the control limits represents a wastage.

Figure 1: Variation and process capability

| Cumulative Waste (%) | |

| UWL | 66% |

| LOL | 65.45% |

| Mµ | 65.62% |

| Sigma | 0.99% |

| Cp | 9.04E-06 |

| UWL-Mµ | 0.00 |

| Mµ-LWL | 0.17% |

| pk | 0.05634 |

| Variance | 9.72222E-05 |

Figure 2: Production process control chart

From the control chart, lack of budgeting and constant redesigning fall within the control limits, implying that the two factors are not major contributors to the wastage. Constant retesting falls within the control limit. This shows that retesting is a critical step during production rather than a waste as it supports the testing teams to ensure the company’s products comply with the approved specifications. However, constant retesting might need a slight improvement through the use of more advanced technologies to increase production efficiency. Accordingly, constant redesigning falls outside the control limit, calling for improvement strategies. Redesigning not only increases the product waiting time but also the consumption of resources that, eventually lowers the firm’s profitability. Even so, constant redesigning is an essential undertaking during the production process. Illustratively evaluating a product design may provide crucial feedback to the testing teams to change the product software per customers’ requirements before releasing it into the market, thereby enhancing competitiveness. Moving forward, constant redesigning falls outside the control limits by a large margin. An attempt to design Apple’s products in line with customers’ specifications to maintain quality leads to significant Waste.

Part 3: Executive Summary

Process Evaluation Summary

The process evaluation of Apple’s NPD utilizes the Six Sigma methodology. Six Sigma methodology uses the DMAIC and DMADV approaches. The DMADV approach is essential for new product development. In this case, the defects that are targeted include delays in the process, excessive costs, and products that fail to meet the needs of the market sufficiently. Apple produces products concurrently while seeking to retain its market leadership as a luxury brand. Loyal clients look out for these new products. However, the length of development is defective because it is not specific. It can be extended due to prototype leakages. This leads to the consumption of more financial resources and time, which is essential due to the short life cycle of products today. As products become obsolete fast, companies such as Apple need to not only churn new products but also provide those that meet the changing needs of the market. Apple’s development process fails to emphasize the needs of the consumers. While the company can use consumers’ buying behaviors as part of research and development, identifying a product that sufficiently fulfills the client’s expectations is challenging. Thus, the input of clients is essential. This will reduce or eliminate the production of defective products and promote acceptance and loyalty from the targeted market.

Furthermore, the need to limit the resources that are dedicated to NPD exists. As observed, financial resources need to be managed in an ingenious manner that ensures significant returns on all investments. It is costly to invest unlimited resources in NPD and have it attract minimal sales due to a defect that compromises its functionality, relevance, and efficiency in the market.

Evaluation Control Summary

The evaluation control charts show that a lack of a budget, redesigning, and retesting may not necessarily lead to a waste of resources. These steps are essential in ensuring that the company’s products lack defects and are competitive. Retesting is critical due to the need to ascertain the product’s functionality. However, it is essential to use advanced technologies to evaluate new products. These should enhance the company’s efficiency significantly. When products need to undergo the designing process multiple times, the lead time increases. During this time, more resources that may not be recovered through the sale of the product are consumed. Therefore, the company should seek to improve the design process.

Six Sigma Effectiveness

Based on the evaluation of the company’s product development process, it is essential to note that the Six Sigma methodology has the potential to improve it significantly. As earlier stated, the method seeks to have companies design their products with customers in mind. Minding the clients’ needs can involve direct surveys, review of client feedback, and going through the ideas that the Research and Development department has identified over time. Seeking out such data provides the company with insight into the client’s unmet needs and preferences. They are then capable of customizing the new product’s design and functionality along these lines. This approach reduces the likelihood of redesigning or rebuilding the product and saves financial resources.

However, retesting is still an essential element because it plays a critical role in eliminating defects. The company can include the clients in this process for more effective feedback. The Six Sigma methodology is promising due to its ability to overhaul the product development process, save on the costs that the company incurs, and reduce any wastages that may occur along the way. Therefore, Apple must adopt the Six Sigma methodology and incorporate it into its process of developing new products.

Recommendations for Improvement

To improve Apple’s current procedure of developing new products, it is essential to include various additional steps in the current process. The main improvements include assembling a team, setting goals and a vision, reviewing the client feedback, reviewing the R&D findings/innovations, determining the appropriate product, allocating a flexible budget and timeline, troubleshooting the product, and adjusting the product to meet market needs. These changes align with the Six Sigma methodology, which is intended to ensure the product meets the client’s needs and is developed within a flexible budget. Troubleshooting after production allows the company to identify defects that the clients may locate when using the new product (Sabri, Mahmood, & Hasrulnizzam, 2018). This process of development is expected to reduce the defects and other inconsistencies that may arise after product launch. Goal and vision setting allows the team to understand the project’s direction and share in the vision (Kouzes & Posner, 2009; Martin, McCormack, & Fitzsimons, 2014). The goals that the company sets are important because they create a direction for the team members. They set the team members in a specific order, reducing the internal resistance. A clear goal eases the entire process and increases the chances of achieving the desired end.

References

Kouzes, J. M., & Posner, B. (2009). To Lead, Create a Shared Vision. Harvard Business Review.

Martin, J., McCormack, B., & Fitzsimons, D. (2014). The importance of inspiring a shared vision. International Practice Development Journal, 4(2).

Panzarino, M. (2012). This is how Apple’s top-secret product development process works—the Next Web.

Sabri, M., Mahmood, A. R., & Hasrulnizzam, W. (2018). Six Sigma Analyze Phase for New Product Development Prototype Process Improvement. International Journal of Engineering & Technology, 7(2.29), 79-85. https://doi.org/10.14419/ijet.v7i2.29.13134

Yousafzai, M. T., Ishrat, R., & Khan, H. U. (2011). A CApple’s story of Apple’s success with the iconic iPod and iPhone.

ORDER A PLAGIARISM-FREWe’llER HERE

We’ll write everything from scratch

Question

Statistical Process Control Methods-Apple

Create a new Word doc for the elements of this assignment.

Evaluate your process using 1 of the following:

Use theWaste concept to find ways to eliminate waste and improve the process.

Use SPC or Six Sigma to reduce defects or variances in the process.

Add your evaluation to your Word doc with” the header “Process” Evaluation.”

Continue to Pt 2: Control Chart and Process Metrics.

Evaluation of Control Chart and Process Metrics

Complete the following in Excel:

Calculate the defined process metrics, including variation and process capability.

Develop and display a control chart for the process.

Evaluate the control chart and process metrics using Statistical Process Control (SPC) methods. Determine whether the process could benefit from the use of Six Sigma, Lean, or other tools. (Include all calculations and charts.)

Write your evaluation in your assignment Word doc under” the header “Evaluation of Control Chart and Pro” ess Metrics.”