Apple Supply Chain

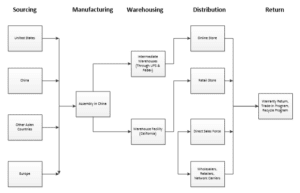

Supply Chain Diagram

Supply Chain Plan

A supply chain plan includes proper coordination of assets to optimize the delivery of services, goods, and information from the supplier to the customer and balancing supply and demand (Scott et al., 2011). It, therefore, requires considering the source of raw materials, how the raw materials are converted into final products, and the distribution of the products to customers. The company will source its products from the United States, Europe, China, and other Asian countries. The company’s representatives will manage the sourcing process in those countries to ensure that there is a proper flow of supplies whenever they are required. The sourced products will then be assembled in China in preparation for distribution in different regions based on customer demands. The assembly process will include using a warehouse facility in Elk Grove, CA, California, and intermediate warehouses via FedEx and UPS. The products in the medium warehouses will then be moved to online stores, and those in the warehouse facility in California will be transferred to retail stores, wholesalers, network carriers, and direct sales forces. Customers will be given a warranty on all products they purchase directly from the company or through retailers, wholesalers, and online stores. Customers will also be allowed to trade in what they have for products being sold by the company. The company will also have a reuse or recycle program to encourage proper waste management and contribute to environmental sustainability.

Value Chain and Flow of Structure

Inputs

Apple focuses on using high-quality raw materials to ensure that its products are of high quality. The company, therefore, sources inputs in different countries based on the availability of the quality they want. As mentioned in the supply chain diagram, inputs will be from different countries, mainly the United States, Europe, China, and other Asian countries. They will include labor and raw materials used to manufacture its devices.

Outputs, including customer service structure

Outputs resulting from the manufacturing process will include the products being sold to customers worldwide. The company’s success will be dictated by the customers’ reception of the products offered, hence the need for a good customer service structure. To begin with, the company will provide a product description to customers to ensure that they understand a product’s features before purchasing it. Customer service will also include a one-year warranty on all products and free maintenance if the device develops issues within the first year of use after purchasing it.

Inventory points and forecasting

Inventory points will include the demand for the company’s products and the availability of raw materials. Demand forecasts will be made to ensure that there is enough supply to meet the demand, thus maintaining customer satisfaction. The company will also regularly access the availability of raw materials to predict any shortages that could affect production and develop solutions to meet needs if they arise.

Sourcing activities

The quality of raw materials used in the production process plays a significant role in determining the quality of the final product (Wang, 2017). Apple has maintained a legacy of producing high-quality products and has ensured that its suppliers understand the quality required. Therefore, sourcing activities will include assessing the quality of inputs offered by suppliers and signing a contract with suppliers to dictate the terms of how supplies should be made and how the company will be paying the suppliers. The souring activities also include hiring employees or workers with the skills and knowledge required to manufacture the company’s products within the required standard. The company will source the right workers based on their work experience and educational background.

Risks

The main risk that could affect the company’s supply chain is a shortage of supplies, mainly due to restrictions being put in place by governments preventing the entry of goods and people from specific countries to prevent the spread of the COVID-19 virus. The company will have to consider sourcing raw materials locally to maintain production. Another risk is the increase in the cost of raw materials, which could force the company to increase the price of its products. The increase in the cost of raw materials is likely to occur due to the harsh economic times created by the COVID-19 pandemic in different countries, including where the company sources its raw materials. Another risk is the production of counterfeit products, hence reducing customer trust in the products, which will reduce sales and profits.

Locations

The company operates globally and has partnered with electronics retailers in different countries to facilitate the availability of its products. The central locations will be where the company sources its raw materials, the assembly point, and where the phones will be distributed. The company will use retailers and the online store to sell its products to different locations. It will also have physical stores in areas with a high demand for its products, such as European countries.

Logistics

The company will have a diverse logistics structure that will include wholesalers, retailers, and online stores. The products sold online will be distributed to customers worldwide via courier services such as UPS and FedEx. The company will also partner with online retailers in different countries to facilitate the delivery of its products to customers. Logistics will be regulated from one central office in China to facilitate effective distribution and monitoring of products, thus enabling the company to plan the manufacturing process based on the flow of products to avoid oversupply and failure to meet the demand.

References

Scott, C., Lundgren, H., & Thompson, P. (2011). Guide to plan in supply chain management. Guide to Supply Chain Management, 9-36. https://doi.org/10.1007/978-3-642-17676-0_2

Wang, Q. (2017). Relationship between raw material quality and product quality of peanut. Peanut Processing Characteristics and Quality Evaluation, 151-209. https://doi.org/10.1007/978-981-10-6175-2_4

ORDER A PLAGIARISM-FREE PAPER HERE

We’ll write everything from scratch

Question

Use the company you chose to work with in the second Competency Assessment of this course.

Build a supply chain plan and diagram for the company by analyzing factors that affect sourcing, logistics, metrics, suppliers, and risk.

Apple Supply Chain

Create your supply chain diagram using one of the following tools:

• Excel

• PowerPoint

• Visio

• Pictogram

• PDF

• Other faculty-approved platform

Write an 875-word analysis of the supply chain operations plan. Include the following in your comment:

• A visual depiction of your supply chain diagram

• Your supply chain plan

• Value chain and flow of structure

• Inputs

• Outputs, including customer service structure

• Inventory points and forecasting

• Sourcing activities

• Risks

• Locations

• Logistics

Submit your assignment.