As-Is Process Flowchart Evaluation

Evaluate the efficacy of your process using process improvement techniques. Write your evaluation below this line.

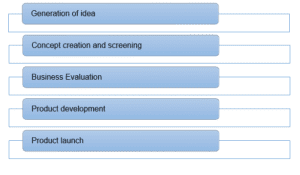

The focus will be on the steps used to create a brand-new product. As was just outlined, there are a total of five steps involved: idea generation, concept creation and screening, business evaluation, product development, and product launch. For innovative goods, this method works well. However, there will always be times when things do not go according to plan. Additionally, little effort is made to examine how the procedure may be improved. So, the procedure needs tweaking so that it can function more effectively. In particular, there is room for advancement in terms of mistake detection during the ideation phase and market testing prior to commercialization.

Process Improvement Flowchart

Determine how the process can be improved based on the results of your evaluation.

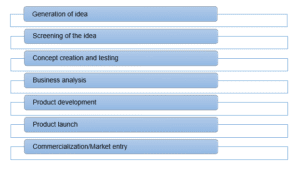

There has to be better mistake identification and market testing in the new product development process before the idea is taken to the commercial stage. To put it simply, the enhancement will aid in the elimination of mistakes and the reduction of associated risks.

Define metrics and measure the current process. Insert the metrics and measures below this line.

Metrics used to evaluate a process’s effectiveness are called “process evaluation metrics” (da Silva et al., 2021). The method incorporates a screening phase and a deployment phase to evaluate the potential of a concept or product. Measurements are very important for ensuring that the end result is a success.

Use process improvement techniques to improve the process. Create a flowchart of the improved process using Microsoft Word, PowerPoint, Visio, or Excel. Use your professional judgment to ascertain how the future process will perform according to your metrics. Insert the new flowchart below.

Summary

The process described here applies to releasing a brand-new commodity on the market. The concept behind the new offering is to help people make their own unique mobile phones. The steps outlined here focus on taking an idea from concept to prototype and then into the marketplace for testing. In its original, non-improved form, the procedure has five phases. Ideation, concept creation and testing, business evaluation, product creation, and market entry are all part of the process. Weaknesses in the above-mentioned approach for developing a personalized mobile phone are apparent. One of the challenges is knowing how well an idea will go in the marketplace before completely commercializing it. The process is strengthened by including elements that may increase the idea’s feasibility and decrease the risk and uncertainty associated with its success (Trienekens et al., 2017). The process can be made more robust by including two new steps: concept screening prior to product creation and test deployment into the market before full marketing.

Six Sigma was utilized to identify problem areas in the process of improvement. Further, the idea of constraints was used as a source of creativity. The theory of constraints takes a methodical approach to remove bottlenecks in a process, as stated by Philipp et al. (2022). We can infer the process’s future effectiveness based on projections of its likely shape. Notably, this is so because the risks have been substantially reduced via prior evaluation and adjustment of the improvement areas. The process is also anticipated to operate exceptionally well because of the implemented process optimization strategies. Their ability to successfully redesign processes has been extensively researched and documented. Initial iterations of the concept for making personalized mobile phones will be subjected to rigorous scrutiny to help shape and refine later iterations. We will further explore and refine the concept based on the preliminary evaluation. The next step is undertaking a market study to gauge interest in the concept before moving forward with product development. After the product has been developed, a single unit will be released into the market as a test before the full-scale marketing campaign begins.

References

da Silva, I. B., Cabeça, M. G., Barbosa, G. F., & Shiki, S. B. (2021). Lean Six Sigma for the automotive industry through the tools and aspects within metrics: A literature review. The International Journal of Advanced Manufacturing Technology, 1-27.

Philipp, P., Tobisch, F., & Matthes, F. (2022). Challenges and Success Factors for Metrics in Large-Scale Agile Development. https://aisel.aisnet.org/amcis2022/sig_itpm/sig_itpm/2

Trienekens, J. J., Kusters, R. J., van Genuchten, M. J., & Aerts, H. (2007). Targets, drivers, and metrics in software process improvement: Results of a survey in a multinational organization. Software Quality Journal, 15(2), 135-153.

ORDER A PLAGIARISM-FREE PAPER HERE

We’ll write everything from scratch

Question

Select a process from an organization you work for or are familiar with. You will also use this process in your Week 2 and Week 4 Assignments.

As-Is Process Flowchart Evaluation

Create a flowchart of the as-is process using Microsoft® Word, PowerPoint®, Visio®, or Excel®. Insert your flowchart below this line.

Evaluate the efficacy of your process using process improvement techniques. Write your evaluation below this line.

Process Improvement Flowchart

Determine how the process can be improved based on the results of your evaluation.

Define metrics and measure the current process. Insert the metrics and measures below this line.

Use process improvement techniques to improve the process. Create a flowchart of the improved process using Microsoft Word, PowerPoint, Visio, or Excel. Use your professional judgment to ascertain how the future process will perform according to your metrics. Insert a new flowchart below this line.

Summary

Write a 350-word executive summary that includes the following:

- A brief description of the process based on the flowchart of the process’s current state

- The results of your process evaluation and how the weak points can be strengthened. Include a description of the process improvement technique(s) used.

- A brief description of process improvements based on the process of the future state

- How do you anticipate the future process will perform based on metrics used to evaluate the process’s current state?

- A description of your process improvement project to achieve the process’s future state